The final bronze sculptures of the earth and the moon are on permanent exhibit in the Gottesman Hall of Planet Earth at the Museum of Natural History in New York City, together with the crust model. (link)

Below is an overview of the manufacturing process of the puzzle pieces for the earth, the moon and the 'earth crust'.

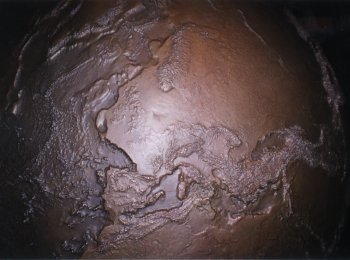

The Earth

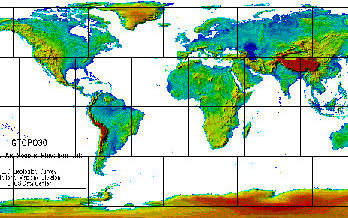

Topographic DataSource: USGS, EROS Data Center. Sioux Falls, South Dakota

Name: GTopo30, v 1.0

Source: National Geophysical Data Center Name: TerrainBase Global DTM Version 1.

The final model of the world measured 42 inches in diameter and was delivered as two hemispheres.

The surface-topography of the data sets were vertically scaled by 22.5 times in order to allow features to be seen clearly.

For each hemisphere I CNC-milled 8 equatorial parts stretching from 0 to 40 degrees latitude and a spread of 45 degrees in longitude, 6 parts stretching from 45 to 80 degrees latitude with a longitude range of 60 degrees and a polar cap with the latitude ranging from 85 to 90 degree and a 360 degree range of longitude.

The GTOPO30 data set which exists as a 30 second resolution was filtered to a 5 min resolution set and merged with the 5 min resolution bathymetric data. The data set was merged and converted to DXF format from DEM format using job specific code.

The dxf data was imported into ALIAS software, aligned, assembled and exported into Euclid3 CAD software using a stereolithography file format. The mapped data set was then used to generate a CNC tool path for each of the 30 pieces. The average computation time of the tool paths for one part was around 10 hours on a (back in the days) screaming Silicon Graphics workstation.

CNC machining the topology

The front sides of the blocks were milled using a tool path created in Euclid and milled using 0.25” and 0.0625” ball end mill tools.With the 0.25” end mill a 0.02” step over was used and on the 0.0625” tool I milled with a 0.005” step over. The milling time per piece averaged around 14 hours on the front sides.

Prior to milling the front, the backside of the pieces were machined as well, to allow for accurate alignment of the pieces during assembly. Check the info section at the bottom of the page if you want to have a look at the process.

The Earth and the Moon

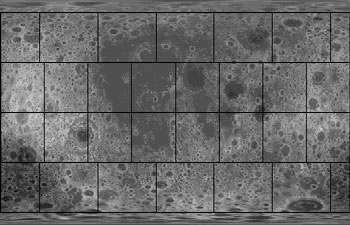

The Moon

Topographic Data Source: Don Davis modified Clementine data

For the moon I used a data set that was supplied as a 255 grey scale image with 2700 x 1350 pixels.

The data was originally from a 30 minute data set which had been resampled and retouched to achieve a 15 min resolution.

The conversion and machining process was the same as for the world.

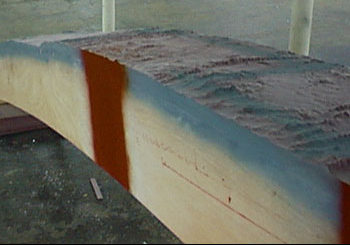

Earth’s crust model

As a 'sideproject', we also milled a cross-section of the Earth' crust, stretching from Alaska to Florida, in a much larger scale.Topographic Data

Source: USGS, EROS Data Center. Sioux Falls, SD

Name: GTopo30, v 1.0

Bathymetric Data:

Source: National Geophysical Data Center

Name: TerrainBase Global DTM Version 1.0

The earth’s crust model was C.N.C. machined with a 0.25” ball cutter from 4” thick pieces of Ren-Shape 450.

It was assembled into a 34 foot long section, 18 inches wide with a radius of 43’ 6”. Toughest part was delivering it in two pieces by truck to Manhattan.

The data was vertically scaled up 5 times. The used DEM data had a two minute resolution, and was merged with Terrain-base Global 5 minute bathymetric data.

Data processing was identical to the world and moon.