Mechanical and Electrical Design for Sterile Fluid Management

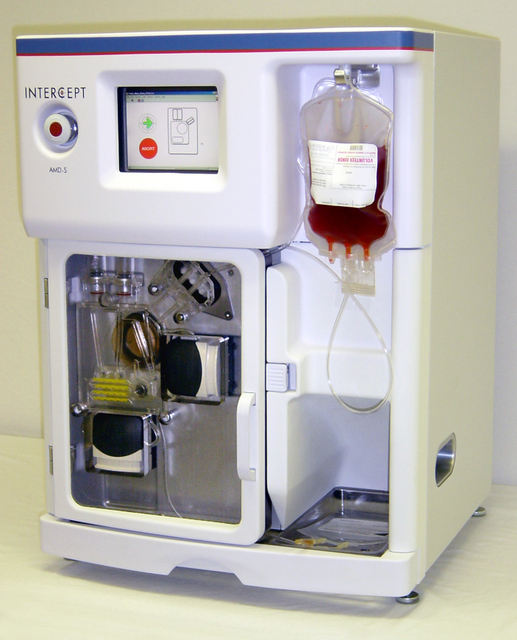

The device I helped develop automatically mixes a two-component chemical with a solvent and 500cc of blood plasma. The solution is then processed in multiple software-controlled mixing and incubation cycles for multiple hours, while the chemicals inactivate any potential pathogens in the process. Once completed, the solution is neutralized and is ready for transfusion afterwards. The entire process had to be automated and controlled to minimize the occurrence of human error. One of the sub-projects was to develop a disposable kit which had to be double contained to prevent exposure of the operator to either the chemicals or the plasma. Numerous components in the kit had to be actuated 'through' the containment layers, creating an additional challenge for the design.See the final product here.

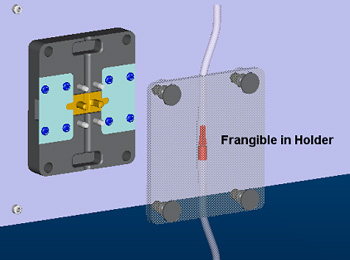

I was working mainly on two of the load cells, needed for weight control of the initial plasma and a frangible breaker module. Frangibles in this case are small, disposable inline stop-valves, which allow fluid to flow through the tubing if an inner plastic stem has been bent back and forth a few times until it breaks off. While pinch-valves were sufficient to control reconstitution of the mix or to adjust varying mixing pattern, they were not deemed reliable enough to either prevent or allow flow in a number of crucial and time critical process steps.

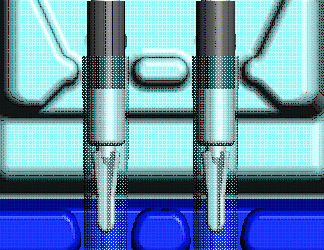

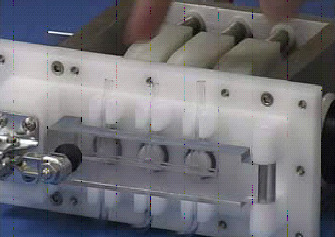

Below is an early feasibility prototype of the frangible breaker. The red piece is the one that blocks the flow until snapped. In this test iteration, only one frangible can be actuated and the slider also moves only linear.

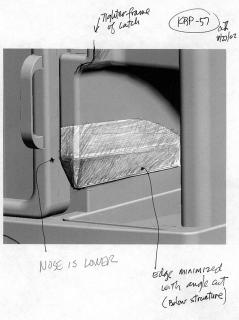

During development, the requirements changed so that the unit now had to actuate two frangible simultaneously and it also had to 'dive' into a plastic containment layer prior to actuation.

Module Requirements

- Actuation through containment layer into disposable tray (travel 0.41”)

- Simultaneously break 2 'European style' frangibles (travel +/- 0.375”)

- Positioning feedback through sensors

- Start drain in less or equal to 5 seconds

- Avoid fluid ingress

- Small footprint of device

- Modular approach, mountable from back

Overview

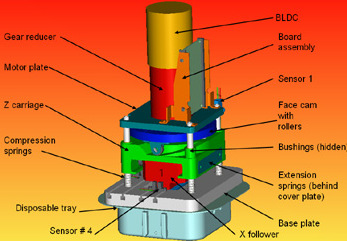

Because the footprint of the individual modules as well as weight/cost were crucial, I attempted to generate both motions (the linear engagement towards the disposable kit/door and the following rocking actuation motion) with just one motor. This was achieved by using a lobe/cam mechanism.

Final functional prototype module

CAD animation

of the actuation/breaking motion in the final functional design (right-click to play).Development of a fully automated pathogen reduction device for blood plasma

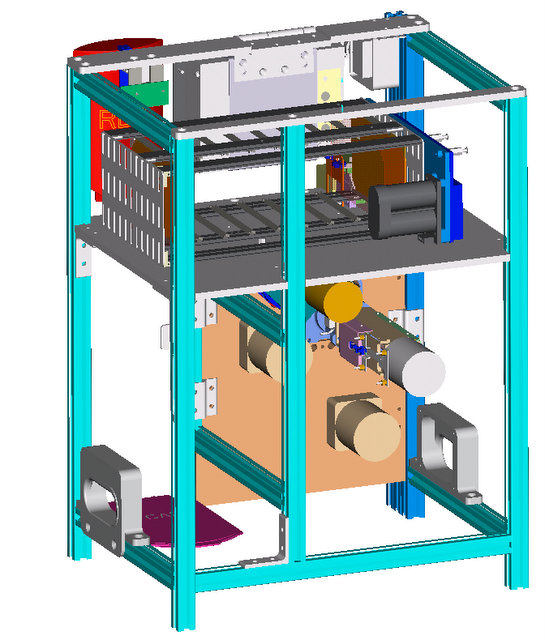

In the course of this project, various sub-systems were developed and virtually 'assembled' using a skeleton in SolidWorks. This method allowed individual people to design their modules, while efficiently working together on the assembly, which was especially critical given the space constraints.

Main modules and their function

- Structural frame and functional covers > Functional accessories to allow for workflow evaluations

- Touch screen monitor and custom controllers > Realistic user interface and process control

- Load cell unit > Weight measurement of plasma

- Proprietary frangible breaker unit > Safely prevents flow of liquid, drains when actuated

- Proprietary reconstitution pump > Mixes powder in a solution, then with another chemical and finally added to the plasma, all within a narrow time window.

- Proprietary valve actuator module > Enables rapid change of fluid distribution patterns

- Proprietary mixing pump > Alternating mixing cycles throughout the incubation period

- Disposable mixing kit > Small, complete kit housing chemicals in vials, tubing and various pump chambers

Frame

The structural frame was built up using modular Bosch aluminum to allow for easy modifications on the prototype.

Pinch valve module

Below you can see the prototype of the 5-valve unit. All actuators are driven by just one motor also.

Covers

|

|

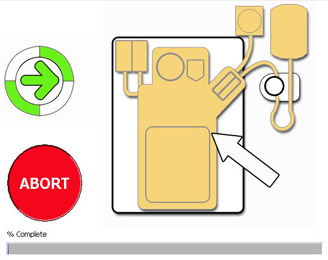

Ergonomics and GUI

Realistic custom user interface

for control and process information (LabVIEW) Realistic custom user interface

for control and process information (LabVIEW) |

Position and design of modules

were optimized based on numerous workflow tests.

Position and design of modules

were optimized based on numerous workflow tests. |

Final Prototypes

Two alternative development tracks allowed for flexible configuration of either conventionally designed components or of more experimental modules for testing.